Document Type : Original Article

Authors

- Zaydoon Kh. Kuraimid

- Kh. E. Ahmed

- Thabit A. Ahmed

- Walled Ismail Omara

- Safaa Dawood Abdul Kareem

- Hadeel Abdul Kareem Hussein Husain

Petroleum Research and Development Center (PRDC)-Ministry of oil, Iraq

Abstract

This study dealt with the problem of produced water (PW) at Missan Oil Company (MOC) which results in huge quantities of water annually from different fields of the company and particularly in Alommara oil field .The produced water is discarded to the evaporation ponds outside the field which causes serious problem to the environment. We studied that problem and how to treat the produced water generated from Alammara Degassing Station for reinjection application to increase the secondary oil recovery. A pilot plant (10m3/day) for PW treatment was manufactured based on some bench scale treatment to select the sequence process to treat the targets parameters. Many parameters were selected to be treated based on its effect on water injection specifications .The selected parameters were Oil and Grease , Iron ,Turbidity ,TSS, Particle Size , Dissolved Oxygen , PH and Bacteria. Removing oil by using corrugated plate interceptor technique (CPI) is the first stage of treatment. In some circumstances, the presence of iron in the produced water needs a treatment to meet the reinjected specifications of water. A chemical oxidant (Sodium Hypochlorite) was used in the pilot plant to oxidize the iron and removed later. The total suspended solids (TSS) are decreased to the required concentration by using coagulation – Flocculation process and dual sand filter media .The other target parameters to be treated in the pilot plant are bacteria and dissolved oxygen. Chemical agents, Gluteraldehyde and Sodium Sulfite were used to treat bacteria and dissolved oxygen respectively. Caustic Soda solution was used to obtain a suitable PH value. The specifications of treated water by this piot plant were very proper for safely reinjection to increase the recovery of oil.

Graphical Abstract

Keywords

Main Subjects

Produced water (PW) is a huge volume produced from the oil drilling. It is a side product from oil wells [1]. PW is water trapped in underground reservoir rocks and is brought to surface along with crude oil and gas. Besides elevated concentration of heavy metals such as Barium, Uranium, Cadmium, Chromium, Strontium and Lead, PW contains dispersed oil droplets, dissolved organic compounds and significant amount of anions, such as Carbonate, Bromide and Sulfate [2]. The physical and chemical properties of produced water vary considerably depending on the geographic location of the field, the geological formation with which the produced water has been in contact for thousands of years, and the type of hydrocarbon product being produced [3]. The water produced is seven to eight volume larger than the oil produced [4]. Untreated produced water causes number of problems due to the existence of high-concentration toxic substances; the inappropriate disposal of oily sludge can pose serious intimidation to the receiving environment. Oily sludge can disturb the physical and chemical properties of soil, leading to soil morphological transform. The oily sludge contaminated soils may create nutrient dearth, reduce seed germination, and cause limited growth or demises of plants on contact. Due to its high viscosity, oily sludge components can be fixed in soil pores, adsorbed onto the surface of soil mineral constituents, or form a continuous cover on soil surface. These would lead to reduced hygroscopic moisture, hydraulic conductivity, and water retention capacity of soils. In particular, the components with higher molecular weight in sludge and their degradation products could remain near soil surface and form hydrophobic crusts that decrease water availability and limit water/air exchange [5].

Characteristics of Produced Water

Natural water or formation water is always found together with petroleum in reservoirs. It is slightly acidic and sits below the hydrocarbons in porous reservoir media [6]. PW is a mixture of injected water, formation water, hydrocarbons and treating chemicals [7].

Current Status of Produced Water in Alommara oil field –MOC

The produced water generated at Alommara oil field is driven into the evaporation ponds outside the field which causes serious problem to the environment (Figure 1).

Figure 1: Discarding the PW into the evaporation pond (This picture was taken during collection the dated in Alommara oil field, latitude 31.79282, langitude 47.0573)

Typical specifications of water for reinjection application

The specifications of water for reinjection application differ from reservoir to another but generally the typical specifications for reinjection applications without causing damage to the reservoir are illustrated in Table 1.

Table1: Typical Specifications of Water for Reinjection*

Treatment of PW generated in Alamara oil Field

Selecting the Treatment Process Sequence

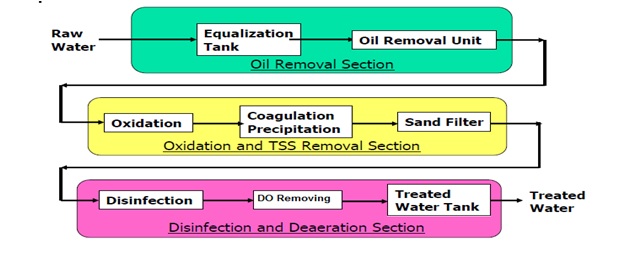

The parameters of PW to be treated were identified and included pH, total iron, TSS, turbidity, particle size, oil content and bacteria. A bench scale treatment of real PW samples was applied to obtain the reasonable results of treated PW before manufacturing the pilot plant. The general philosophy of PW treatment for reinjection application was selected precisely by the joint research team as illustrated in Figure 2 below.

Figure 2: The sequence treatment in the pilot plant (This figure was prepared by the research team)

The Major Parts of the Pilot Plant

The pilot plant of PW treatment consists of the following major parts:

Oil removing unit

This unit consists of the following parts:

- Ø Equalization tanks (5m3 x 2).The material tank is PVC (polyvinyl chloride).

- Ø Circulation pump for produced water.

- Ø Pump for pumping of raw produced water to the corrugated plate interceptor (CPI).

A Corrugated Plate Interceptor (CPI) was used in the pilot plant because it is more suitable to remove the high concentration of oil, assuming that the real PW has high content of oil. A CPI consisting of corrugated interceptors was manufactured from polymer materials. The number of plates per Plate pack was also factored to a certain extent on economy of size of the separator. The number of Plate packs per TPI/ CPI separator was calculated based on the effluent flow and its characteristics to the unit. It is designed to treat PW with less than 1000 ppm of oil content .The mechanism of removing oil from water by using this method depends on gravity and does not need energy for operation.

Oxidation Unit (Iron concentration decreasing Stage)

In this stage of PW water treatment, the concentration of iron is decreased by oxidation process. The presence of Iron in reinjected produced water without treatment can drop out creating emulsions and plugging [8]. Iron can be present in two states, Ferrous and Ferric.

Sodium hypochlorite solution (Bleaching solution) with adjusted concentration was added to the oxidation unit to oxidize Fe2+ to Fe3+ (precipitate) by keeping PH value of the water in the reactor at 7 by using caustic soda solution under automatic control. The precipitate formed was removed in coagulation –sedimentation and filtration operations later on the treatment stages.

The oxidation tank with mixer was used for chemical oxidation. The oxidation tank with mixer was to mix oxidant with produced water. In the test plant, sodium hypochlorite (NaClO) was used as oxidant. Sodium hypochlorite injected 2 mole equivalent corresponding into iron concentration in produced water. Fe2+ in Produced water was oxidized to Fe3+ using oxidation capacity of NaClO. Caustic soda (NaOH) was also injected into the oxidation tank for the pH adjustment. The pH of PW is necessary to adjust approximately pH 7 in order to avoid the acidic condition that causes chlorine gas emission at the oxidation tank.

The equation of oxidation is:

2 Fe+2 + OCl- + H2O 2 Fe+3 + Cl- + 2OH-

Sodium hypochlorite was used as oxidizing agent from different chemicals because it is cheap, available and, as a liquid, does not need dissolving like other oxidizing agents like powder of KMnO4.

Coagulation –Floculation,Clarification unit

TSS are removed by using particular chemicals in combination process (coagulation and flocculation). The chemicals used in this process are called coagulant and flocculent.

Filtration

To remove the residual suspended solids after coagulation and flocculation process, the pilot plant was provided with two sand filters, namely, A and B, with three different materials as a media to obtain the required specifications of TSS, turbidity and particle size for treated PW to be reinjected safely in the reservoir in the oil recovery process. Media of sand filters (Supporting gravel, Sand and Anthracite) were provided by Alnawafiz for sand and gravel production –Baghdad. The particle sizes of the material were tested as Table 2 shows.

Table 2: The Particle size of anthracite and sand

Disinfection

Most often oil and gas produced waters are allowed to either accumulate in storage tanks or ponds until further disposed of or treated for reuse. During this detention time, bacterial growth can occur and proliferate. These bacteria in turn can cause negative effects on treatment and reuse application[9]. Bacteria that are responsible for many problems in the oil industry may be broadly classified as either sessile, attached to surfaces associated with biofilms, or planktonic, free floating. gluteraldehyde was used as disinfectant agent.

Oxygen Removing

Oxygen is not found naturally in produced water. When produced water is brought to the surface and exposed to the atmosphere, oxygen will be absorbed into the water. Water containing dissolved oxygen can cause severe and rapid corrosion [10]. The joint research team designated that 2 mg/l is the maximum concentration of the dissolved oxygen in PW. In the pilot plant, sodium sulfite solution (Na2SO3) was used as an oxygen scavenger to decrease the concentration of dissolved oxygen in the treated PW. The chemical reaction of this process is as below:

Na2SO3 + ½ O2 → Na2SO4

Selecting the proper chemicals to use in PW treatment in the pilot plant

The following chemicals were selected to use in the pilot plant Table 3.

Table 3: The chemicals used in the pilot plant

Laboratory Test of PW samples

A produced water generated in Alommara degassing station was tested. Table 4 represents some tested parameters.

Table 4: PW Analysis [1]

It is noted that the concentration of oil content is low while the concentrations of turbidity, iron, pH and dissolved oxygen are relatively high. PW could not be reinjected without treatment to prevent damage in the reservoir. Another sample was analyzed (Table 5).

Table 5: PW Analysis (2)

Preparation of chemicals

Table 6 represents the preparation of chemicals used in the pilot plant.

Table 6: Preparation of chemicals used in the Pilot Plant

The instruments and standard methods used in efficiency evaluation of the pilot plant:

The parameters of raw and final treated water were measured by two types of instruments, portable instruments and internal sensors assembled in the pilot plant. Table 7 shows the types of the instruments and the standard methods of analysis.

Table 7: The applied instruments and standard methods for water testing

Result and Dissection

The obtain results from the operating of the pilot plant

Proper specifications of treated produced water for reinjection application were obtained from operation of the pilot plant (Figure 3). The selected philosophy in treating produced water proved reliability concerning the parameters that should be treated for reinjection purposes. Table 8 illustrates the results of the pilot plant evaluation.

Table 8: The Results of the Pilot Plant Evaluation

Figure 3: The Pilot Plant of produced water treatment

Conclusion

The philosophy of produced water treatment applied in this study is the first of its kind including all the factors relating to safe injection of water in petroleum reservoirs to increase the secondary recovery of oil. The parameters treated in this study included oil content, iron, tss, turbidity, partial size, bacteria, dissolved oxygen, and pH. A full scale project document (7950 m3/day) was achieved and delivered to the Iraqi petroleum companies. A research team recommends the Iraqi petroleum companies to obtain benefits from the outcomes study to provide a good source for water injection and never discard the polluted produced water to the evaporation ponds which causes a serious problem for the environment.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Authors' contributions

All authors contributed toward data analysis, drafting and revising the paper and agreed to be responsible for all the aspects of this work.

Conflict of Interest

We have no conflicts of interest to disclose.

HOW TO CITE THIS ARTICLE

Zaydoon. Kh. Kuraimid, Kh. E Ahmed, Thabit. A. Ahmed, Walled Ismail Omara, Safaa Dawood Abdul Kareem, Hadeel Abdul Kareem Hussein. Treatment of Produced Water Generated at Alommara Oil Field-Missan Oil Company, IRAQ for Reinjection Application, Chem. Methodol., 2021, 5(4) 348-355

DOI: 10.22034/chemm.2021.132479